TomCat460 Evo

Description

The TMC460Evo® series by HDT includes a complete range of digital servo drives in single-axis execution for operation on 400VAC networks with current sizes up to 3A corresponding to nominal powers up to 2W.

TMC460Evo® allows the motor control of brushless, asynchronous, DC PM and linear servomotors.Piloting both from analog reference and from EtherCat, ProfiNet, CanOpen and Modbus protocol.

Feedback from incremental encoders, SSI absolute encoder and resolver.

TMC460Evo® integrates speed, torque, positioner, electric axis, electronic cam and pressure control as standard.

An Ethernet port allows connection to the corporate network and also remote monitoring.

Easy to program, they connect via the USB port to the fast Caliper management software..

Main Features

Control method |

||

| Digital regulation loop for torque, speed and position. |

- for AC brushless synchronous motor,rotary and linear: FOC control, SVM modulation, with feedback or sensorless. |

|

Main reference |

||

| Analog |

±10V differential speed and torque 12Bit |

|

Auxiliary reference |

||

| Analog |

0/+10V single ended - 12Bit |

|

Frequency reference |

||

|

Speed and position |

- Pulses and direction ( 2MHz ) |

|

Optional fieldbuses |

||

|

- Modbus RTU |

||

Main feedback |

||

|

Hall's sensor |

- with sequence at 120° angle |

|

|

Encoder |

- Incremental 5V Line Drive with/without Hall sensors ( adjustable power supply from 5 to 9) |

|

|

Sensorless |

- Sensorless control for asynchronous FOC and V / Hz control |

|

Second optional feedback |

||

|

Resolver |

- 2 poles Resolver. A/D converter at 16 Bit with simjulated encoder ouput 5V Line Drive. |

|

Encoder output |

||

|

Simulated encoder |

- Incremental Enc. 5V Line Drive (only for resolver): possibility to select 256, 1024, 4096 or 16384ppr |

|

| Repetition |

- ABZ channels repetiotion of the main feedback |

|

Control mode |

||

|

Speed |

- Speed with/without torque limiti. Adjustable trapezoidal or "S" ramps. |

|

| Torque |

- Torque control |

|

| Position |

- Multi-positioner: Single target, from cyclic/acyclic table, analog |

|

| Pressure |

- Pressure control |

|

Configurable inputs and outputs |

||

|

Input |

- 6 digital inputs NPN/PNP (2 Touch Probe) |

|

| Output |

- 3 digital inputs NPN/PNP |

|

Digital filters |

||

|

- Observer on motor feedback. |

||

Drive and motor protection function |

||

|

- Shortcircuit |

||

Drive interface |

||

|

- 3 LEDs on the drive for signaling status and alarms. Complete information via fieldbus. |

||

Hardware Safety Functions |

||

|

- STO : safety input Safe Torque Off according to IEC61800-5 - SIL3 Cat.0: EN61508 |

||

Software Safety Functions |

||

|

- Emergency or Fault reaction stops: By inertia - in Ramp - in Torque Limit |

||

Braking management |

||

|

- Integrated brake management with immediate or ramp stop |

||

Drive parametrization |

||

|

- Via CALIPER 4.0 software through the microUSB 2.0 port |

||

Additional features |

||

|

- Motor autophasing procedure available for every type of feedback. |

||

Current Sizes

| Sizes ( current ) | U.m. | 1.5 | 3 |

| Power supply | VAC | 400VAC 3Ph |

|

| Min/Max supply voltage | VDC | 400VAC ±15% - 50/60Hz |

|

| DC Min/Max supply voltage | VDC | 400 VDC ÷ 700 VDC |

|

| Rated current | Arms | 1.5 | 3 |

| Peak current for 2” | Arms | 3 | 6 |

| Max output power |

KW | 0.9 | 1.8 |

| Max output power (DC brushed) | KW | 0.75 | 1.15 |

| Control method | IGBT / PWM, sinusoidal or trapezoidal for synchronous motors for DC motors with permanent magnets and asynchronous motors. | ||

| Internal braking resistor | W | NO | |

| Output for external braking resistor |

YES | ||

| Suggested external braking resistor (optional) |

R90W 100R | ||

| EMC filter | EXTERNAL OPTION ( according to EMC 61800-3 cat.C2 e C3 ) | ||

| Logic supply | VDC | 24VDC ± 20% | |

| Dynamic forced ventilation | NO | YES | |

| Dimensions | T0 | ||

| Weight | Kg | 1 | 1.2 |

| Safety functions | STO - Safe Torque Off: IEC61800-5-2:2007 - SIL3 Cat.0: EN61508:2001 ( EN954-1:1996 ) | ||

| *= ( according to EMC 61800-3 cat.C3) |

|||

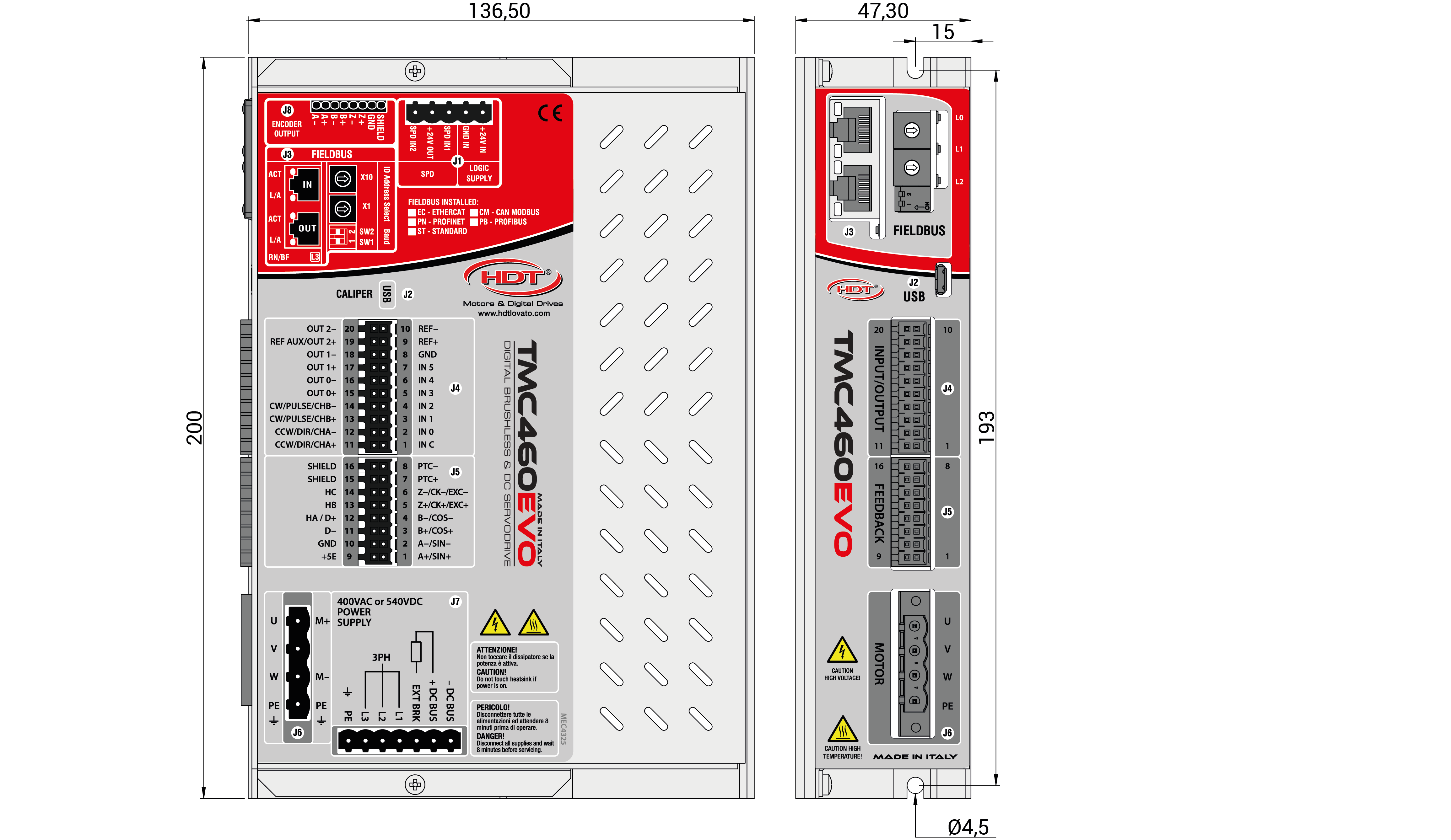

Dimensions