Servomotor type BH10

High dynamic servomotors with natural air cooling. 100mm square case flange and three body lengths. Stall torques in S1 service from 4.7 Nm up to 11.5 Nm.

Electrical data

| Version for 400VAC power supply |

Symbol | U. M. | BH10S | BH10M | BH10L | |||

| Drive power supply voltage |

400VAC | |||||||

| Stall Torque at 100K Δt |

To | Nm | 4,7 | 8,9 | 11,5 | |||

| Rated speed | n | RPM | 1500 | 3000 | 1500 | 3000 | 1500 | 3000 |

| Power at rated speed at 100K Δt | Pn | W |

701 | 1326 | 1263 | 2190 | 1604 | 2589 |

| Torque at rated speed at 100K Δt | Tn |

Nm |

4,46 | 4,22 | 8,04 | 6,97 | 10,2 | 8,24 |

| Peak Torque with S3 10% at 100K Δt | Tpk |

Nm |

12,6 | 24 | 31 | |||

| Poles | PN | 10 |

||||||

| Winding resistance 20°C phase/phase | Rw |

Ohm |

10 | 2,86 | 5,62 | 1,76 | 3,68 | 1,18 |

| Inductance phase/phase 50Hz | Lw |

mH | 105 | 30,2 | 66,5 | 20,7 | 51,2 | 16,5 |

| EMF constant ref. at 20°C | Ke | V/Krpm | 129 | 69,1 | 152 | 84,7 | 159 | 90,4 |

| Torque constant at 100K Δt | Kt | Nm/A | 1,96 | 1,05 | 2,37 | 1,32 | 2,42 | 1,37 |

| Rated voltage at 100K Δt | Vn | V |

268 | 273 | 288 | 301 | 292 | 308 |

| Stall current at 100K Δt | Io |

A | 2,36 | 4,4 | 3,72 | 6,67 | 4,78 | 8,43 |

| Rated speed current at 100K Δt | In |

A | 2,28 | 4,03 | 3,39 | 5,26 | 4,22 | 6,02 |

Mechanical data

| Motor type BH10 |

Symbol | U. M. | BH10S | BH10M | BH10L |

| Rotor inertia | Jm | gm2 | 0,32 | 0,59 | 0,86 |

| Rotor inertia (motor with brake) |

Jmb | gm2 | 0,38 | 0,65 | 0,92 |

| Mass |

M | Kg | 3,7 | 5,7 | 7,7 |

| Mass with brake |

Mb | Kg | 4,8 | 6,8 | 8,8 |

Thermal data

| Motor type BH10 |

Symbol | U. M. | BH10S | BH10M | BH10L |

| Reference and operating conditions | °C | 0÷40 | |||

| Insulation class | Class F | ||||

| Cooling system | Natural air: IC410 (not ventilated) |

||||

| Protection degree |

IP65 (shaft excluded) |

||||

Brake parking data

| Motor type BH10 |

Symbol | U. M. | BH10S | BH10M | BH10L |

| Brake type | 06 | ||||

| Static brake torque at 20° / 100°C* | Tb | Nm | 9 / 8 | ||

| Brake power at 20°C | Pb | W | 18 | ||

| Coupling time | ms | 7 | |||

| Release time | ms | 40 | |||

| Drive voltage ±5% | VDC | 24 | |||

| Backlash | Arcmin | 0 | |||

| * Torque obtained after running-in | |||||

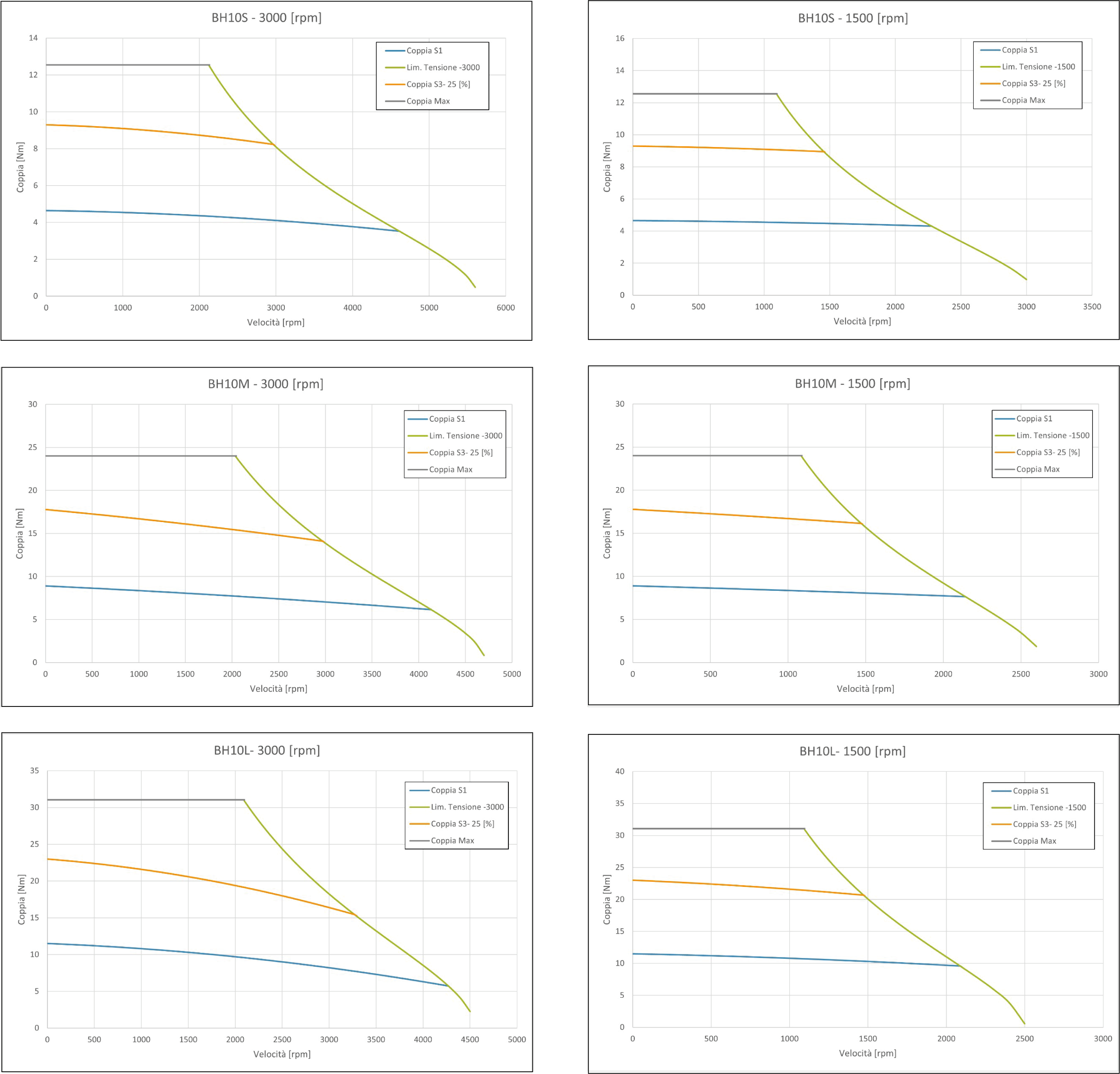

Torque curves

Standard technical specifications

Type |

||

|

- High density permanent magnet synchronous servo motor of couple. |

||

Rotor |

||

|

- rare earth permanent magnets ( NdFeB ) |

||

Winding |

||

| Standard |

- 1500rpm |

|

| On demand |

- other combinations of voltage and speed possible.. |

|

| Insulation |

- class F |

|

Thermal protection sensors |

||

| Standard |

- by means of PTC |

|

Cooling |

||

|

|

- natural air IC410 (not ventilated) |

|

Standard protection |

||

| Standard |

- IP65 (shaft side excluded) |

|

| Optional |

- Seal ring. IP65 protection on the shaft side must be requested and is considered effective only in the presence of an oil bath coupling or with the presence of lubricant. |

|

Ballbearings |

||

|

- ball bearings with double shield lubricated for life |

||

Balancing |

||

|

- grade G6,3 according ISO 21940-11 |

||

Axis/flange concentricity and perpendicularity |

||

|

- grade "N" (normal) - according IEC 72 - DIN0530 |

||

Shaft output |

||

|

- with key, with coaxial threaded hole |

||

Brake |

||

| Optional |

- permanent magnet parking brake, 24VDC power supply with determined polarity.Brake engaged in the absence of power. |

|

Connections and cables |

||

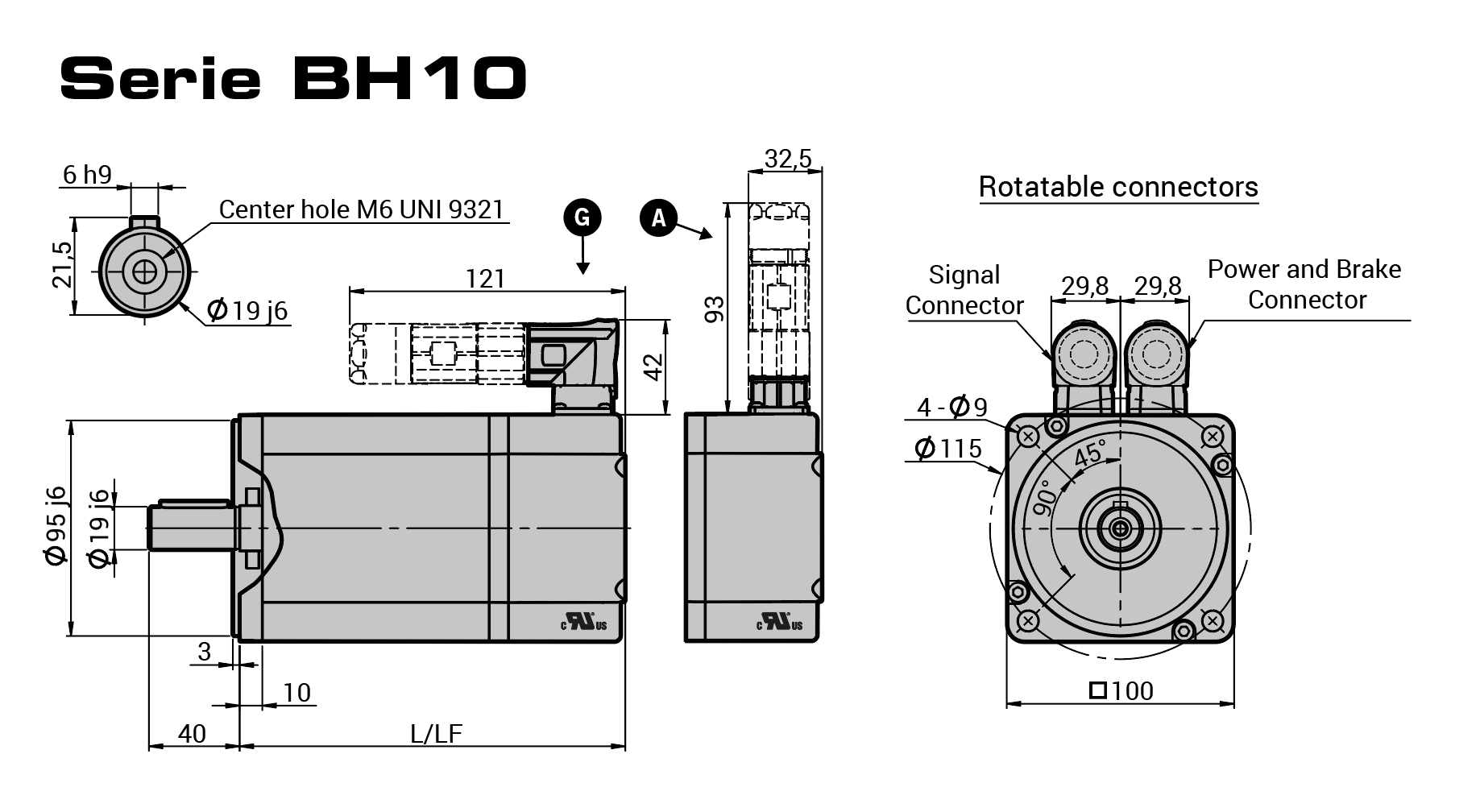

| Power and brake | - with vertical connector type M23 (A code) - with M23 type rotatable angular connector (G code) |

|

| Signal | - with vertical connector type M23 (A code) - with M23 type rotatable angular connector (G code) |

|

Feedback

Resolver |

||

| Code - 1 |

- 2 poles resolver |

|

Incremental Encoder |

||

| Code - 2 * |

- Incremental optical encoder at 1024imp./rev. with Hall sensors arranged at 120° - 5V line drive voltage |

|

| Code - 200 |

- Incremental optical encoder at 2500imp./rev. with Hall sensors arranged at 120° - 5V line drive voltage |

|

| Code - 280 |

- Incremental magnetic encoder at 1024imp./rev. with Hall sensors arranged at 120° - 5V line drive voltage |

|

Absolute encoder |

||

| Code - 412 |

- Absolute optical single-turn encoder BiSS-B with 22 Bit resolution and SinCos channels |

|

| Code - 480 |

- Absolute magnetic single-turn encoder SSI with 12 Bit resolution and SinCos channels |

|

| Code - 512 |

- Absolute optical multi-turn encoder BiSS-B with 22 Bit per turn and 12 Bit multi-turn resolution and SinCos channels 2048imp./rev. |

|

| Code - 521 * |

- Absolute inductive multi-turn encoder ENDAT 2,2 Safety with 19 Bit per turn and 12 Bit multi-turn resolution |

|

| Code - 570 * |

- Absolute magnetic multi-turn encoder BiSS-C with 17 Bit per turn and 16 Bit multi-turn resolution batterlyless |

|

* On request, contact the sales department |

||

Dimensions

| Motor type |

L | LF | Note | ||

| BH10S |

170 | 217 | 1) the oil seal is mounted only if an oil bath coupling is foreseen | ||

| BH10M | 210 | 257 | |||

| BH10L | 250 | 297 | |||

| DISEGNI | Download 3D | ||||